The post Bodine Wins Silver for 2024 LEAP Awards appeared first on Bodine - Gearmotor Blog.

]]>

Design World’s VP, Editorial Director Paul J. Heney and Executive Editor Lisa Eitel presented the winners of the 2024 LEAP Awards on October 30th, 2024, in an online broadcast. These brands cross four of the company’s design engineering brands: Design World, Fluid Power World, Engineering.com, and EE World. This year’s winners were chosen by an independent judging panel of 10 engineering and academic professionals.

Bodine Won Silver

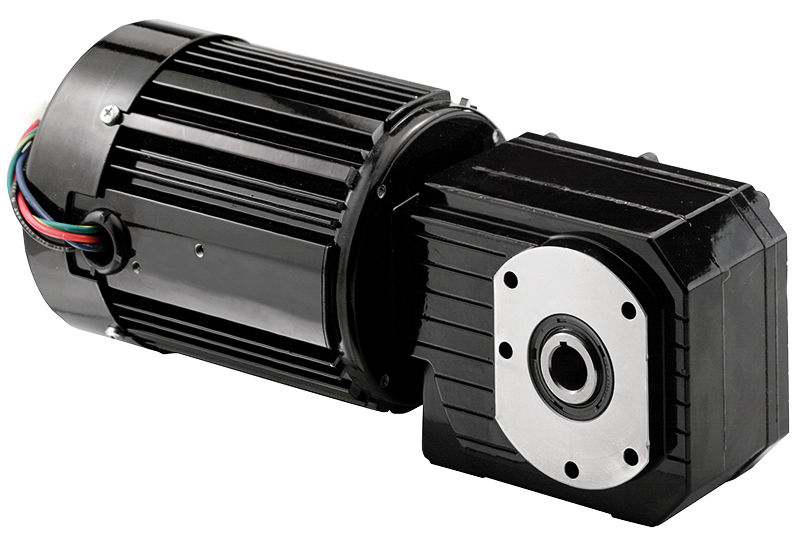

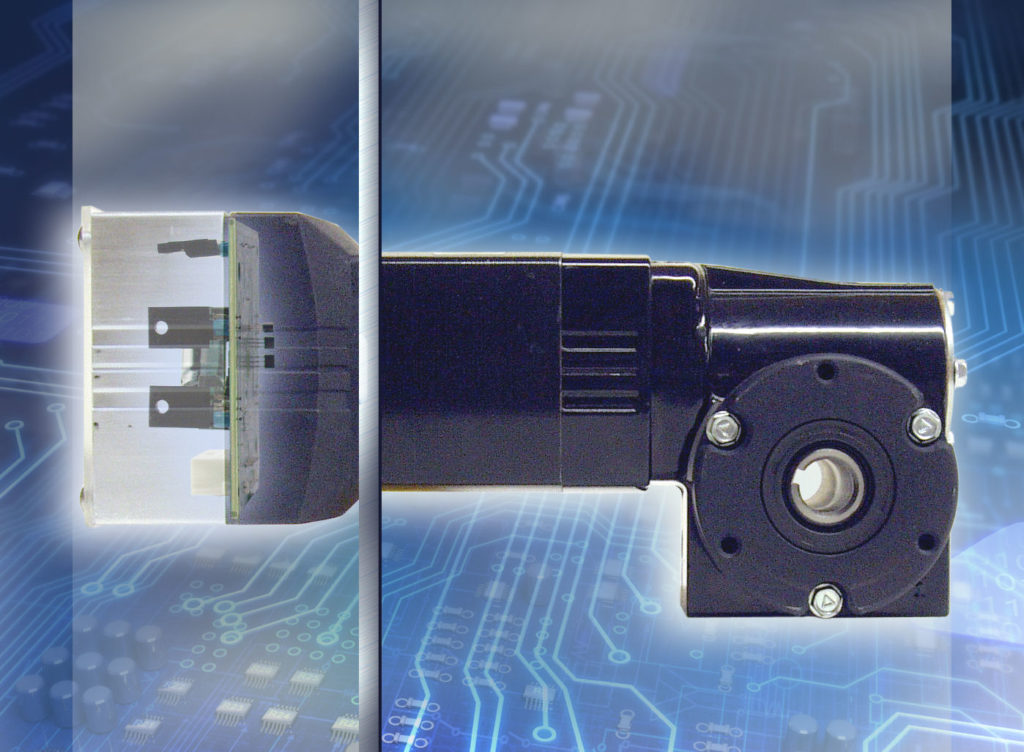

Bodine Electric Company won Silver in the Mechanical category. The product nominated in question is the Type 42R Motor Redesigned for Wet Environments. Bodine Engineers worked exclusively to construct this motor to better accommodate the needs of future customers. This motor is a TENV (Totally Enclosed, Non-Ventilated) version of the original 42R motor. The exterior center ring was redesigned all while retaining the rotor and stator.

The Re-Design in Detail

A new center ring features a smoother exterior surface without fins. The O-rings at each joint were also taken into consideration and designed with an ingress protection rating of IP-66 (IP-66 means that the enclosure is protected from high-pressure water jets in any direction). With the removal of the fan and shroud, it allows the creation of an integral wiring compartment, which enables the motor to fit easily into narrow spaces without the need of a terminal box. Terminal boxes are typically mounted on the side of the motor, which would take up too much space. The accompanying photo shows the original 42R fan-cooled design on the left (with a terminal box mounted on the side) and the new 42R water-protected design on the right (with the end cover removed to show the integral wiring compartment). The first product to use the new motor design is Bodine’s type 42R hypoid series gearmotor.

Thank You

Thank you to the judges and academic professionals that voted for our product. We also thank Design World for featuring us. Congratulations to Ogura Industrial Corporation in winning the Gold in the Mechanical category for their Power-Off Micro Clutch.

The post Bodine Wins Silver for 2024 LEAP Awards appeared first on Bodine - Gearmotor Blog.

]]>The post What Does IP-69K Mean for Stainless Steel Gearmotors? appeared first on Bodine - Gearmotor Blog.

]]>Click here for the full article.

Copyright Bodine Electric Company © 10/2023. All rights reserved.

The post What Does IP-69K Mean for Stainless Steel Gearmotors? appeared first on Bodine - Gearmotor Blog.

]]>The post Typical Operating Conditions for AC Gearmotors and Motors appeared first on Bodine - Gearmotor Blog.

]]>With this new Tech Note from our engineering team, you’ll learn how operating a gearmotor or motor above or below the ratings shown on its product nameplate can affect performance. For standard gearmotors, the torque rating shown on the product nameplate (or in the manufacturer’s sales literature) represents a complete gearmotor rating and reflects the capacity of the limiting gearmotor design elements. Some of the design limitations considered are: motor input power, strength or wear rating of the gearing. Click here for the full article.

Copyright Bodine Electric Company © 06/2022. All rights reserved.

The post Typical Operating Conditions for AC Gearmotors and Motors appeared first on Bodine - Gearmotor Blog.

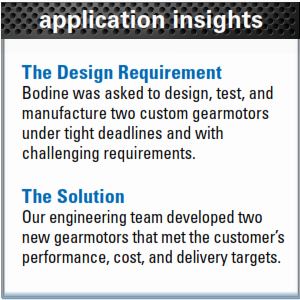

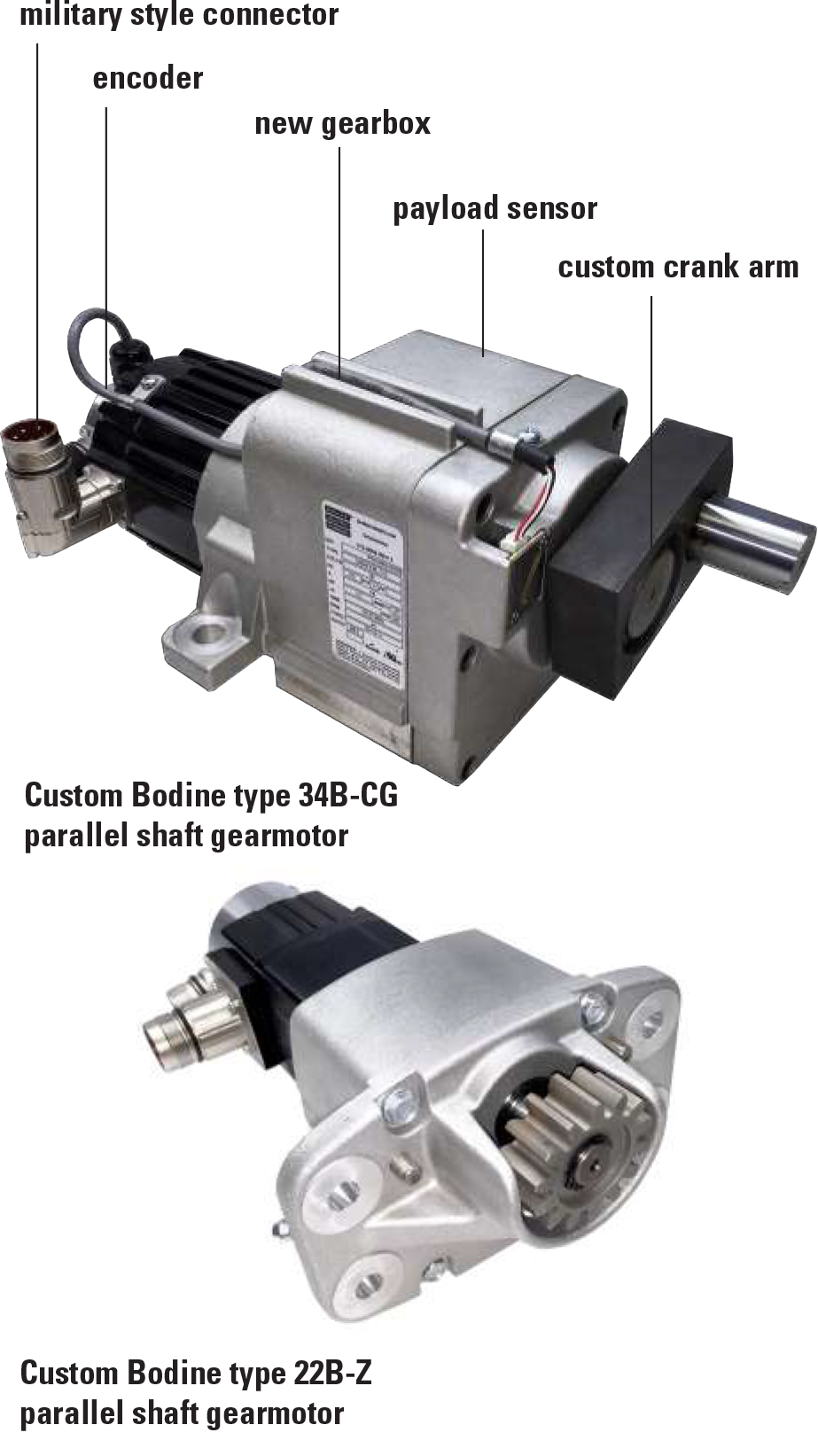

]]>The post Custom Gearmotors Solve AGV / AMR Challenge appeared first on Bodine - Gearmotor Blog.

]]> Large distribution warehouses operated by wholesalers, retailers, or large manufacturers have turned to Automated Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs) to keep up with ever-increasing demand for faster and more economical deliveries. A major original equipment manufacturer (OEM) for AGVs contacted Bodine Electric Company to help develop two new custom gearmotors for their latest AGV. Bodine has since built, tested and shipped over 50,000 gearmotors to this customer.

Large distribution warehouses operated by wholesalers, retailers, or large manufacturers have turned to Automated Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs) to keep up with ever-increasing demand for faster and more economical deliveries. A major original equipment manufacturer (OEM) for AGVs contacted Bodine Electric Company to help develop two new custom gearmotors for their latest AGV. Bodine has since built, tested and shipped over 50,000 gearmotors to this customer.

The Challenge

The OEM’s specifications required two gearmotors, one of them had to lift up to 1,000 lbs (with substantial peak loads). The AGV’s chassis had already been finalized, and left only limited space for the new gearmotors. The gearmotors were required to operate almost continuously for five years, under worst-case environmental conditions, and would be subjected to extreme vibration and shock.

The Result

Almost every part of these new gearmotors was engineered to match the customer’s extensive list of requirements.

- Low-voltage brushless DC motors paired with all-new, highly efficient gearboxes prolong the AGV battery life and minimize downtime

- Gearbox designed to simplify the assembly process of the AGV

- Custom output shaft assembly designed for extremely heavy loads

- Feedback device tracked the position of the drive shaft

- 1024 PPR encoder provided servo feedback to control the gearmotors

- “Military Style” plug and screw connections

- Temperature sensors monitor gearmotor performance and to prevent overloads

- Manual over-ride in the event of a power failure

With Bodine’s help, these sophisticated robotic vehicles have been performing flawlessly all over the world. Bodine not only developed two entirely new gearmotors for the application, they also helped navigate the difficult third-party approval process. Bodine engineers extensive experience in motion control made them an ideal partner in the development of this new product, which in turn is making warehouse jobs easier, more productive, and cost-efficient.

With Bodine’s help, these sophisticated robotic vehicles have been performing flawlessly all over the world. Bodine not only developed two entirely new gearmotors for the application, they also helped navigate the difficult third-party approval process. Bodine engineers extensive experience in motion control made them an ideal partner in the development of this new product, which in turn is making warehouse jobs easier, more productive, and cost-efficient.

Bodine Electric engineers bring over 115 years of application engineering and problem solving experience to a wide range of applications in industries as diverse as medical, packaging, industrial automation, and solar powered outdoors equipment. We look forward to working with you on your next FHP gearmotor design challenge.

To download this article as a PDF, click here

Copyright Bodine Electric Company © 10/2021.

All rights reserved.

The post Custom Gearmotors Solve AGV / AMR Challenge appeared first on Bodine - Gearmotor Blog.

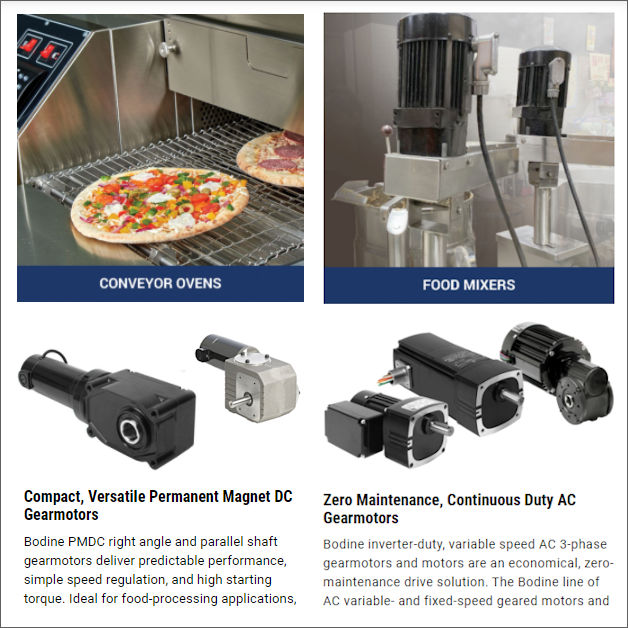

]]>The post Gearmotors for Commercial Food Equipment appeared first on Bodine - Gearmotor Blog.

]]>https://www.bodine-electric.com/industries/food-equipment

#fractionalHorsepower #gearmotor #FoodEquipment #FoodProcess #cookingEquipment #conveyorOven #pizzaOvens #foodMixers #mixers #capping #baggers #AC #inverterDuty #variableSpeed #BLDC #PMDC #gearmotors

Copyright Bodine Electric Company © 07/2021. All rights reserved.

The post Gearmotors for Commercial Food Equipment appeared first on Bodine - Gearmotor Blog.

]]>The post Gearmotors for Hazardous Locations appeared first on Bodine - Gearmotor Blog.

]]>

Our Class I, Division 2 gearmotors meet NEC standards for use in environments where flammable gases or vapors may accidentally be spilled or leak into the operating area. Class I, Division 2, brushless DC (EC) products are available with our 34B/SR-WX gearmotor (with built-in speed control). Fixed speed 34R6BFPP-FX (PSC) and variable speed (inverter duty, 3-phase) 34R4BFPP-FX AC products are available with our larger type FX gearhead (shown below on the right). Our CI/D2 gearmotors are supplied with factory-installed terminal box and meet IP-44.

Our Class I, Division 1 gearmotors and motors are engineered to be used in environments where ignitable concentrations of flammable gases, vapors or liquids are likely to exist under normal operating conditions. Three-phase AC and brushless DC (EC) gearmotors and motors are available with optional CID1 terminal box. These new CI/D1 explosion-proof products meet IP-66.

These geared motors and motors are designed for demanding industrial and commercial applications such as scientific and laboratory equipment, chemical processing equipment, pumps, packaging equipment, conveyors and other factory automation equipment in hazardous locations. Our low-voltage models are ideal for mobile agricultural applications, battery or solar powered portable medical devices, chemical injection pumps in remote gas or oil fields, and any other HazLoc applications that run on 12V or 24VDC.

Custom Gearmotor Solutions for Hazardous Locations

Our engineering team can work with you to design a motion control system that precisely meets your needs. From custom cables, connectors, and windings, to special motors shafts external modifications, brackets, and conduit boxes, almost every component of a Bodine gearmotor, motor or control can be modified. We also offer an extensive array of pre-designed options.

Bodine offers various built-to-order / custom options for our hazardous locations CI/D1 or CI/D2 motors and geared motors. For example, we can design custom windings, drive shafts, mounting brackets or factory-install our base kit, model 0931, to our CI/D1 gearmotors and motors.

- Oil & Gas/Chemical Injection Pumps

- Paint Spray Booths/Industrial Painting

- Food Processing (except for powders and flour)

- Process and Chemical Industry; Cannabis Oils (CBD/THC)

Gearmotors for Applications Where Good Enough is Simply Not Good Enough

When you choose a Bodine gearmotor, motor or control you get more than just the nameplate ratings. You get peace of mind. Whether you are designing a new machine or simply upgrading existing machinery, you can count on our team to make sure you have a motion control solution that will be reliable, efficient, and trouble-free for years to come. We design our rugged, high-performance gearmotors for equipment where downtime is not an option.

Bodine offers over 1,400 standard/stock products with gear ratios from 4:1 to 3600:1, torque to 1,535 lb-in (173 Nm) and horsepower up to 3/4 hp (560W), all available from our centrally-located manufacturing facility in Peosta, Iowa. If none of our stock products fit your needs, let our engineers help you create a custom solution that precisely matches your design specifications.

For more product information, click here.

Copyright Bodine Electric Company © 04/2021. All rights reserved.

The post Gearmotors for Hazardous Locations appeared first on Bodine - Gearmotor Blog.

]]>The post PMDC Gearmotors for Stairlift Applications appeared first on Bodine - Gearmotor Blog.

]]>More info at https://www.bodine-electric.com/custom-solutions

Copyright Bodine Electric Company © 03/2021. All rights reserved.

The post PMDC Gearmotors for Stairlift Applications appeared first on Bodine - Gearmotor Blog.

]]>The post AC Inverters (VFDs) for Variable Speed Applications appeared first on Bodine - Gearmotor Blog.

]]>AC inverter-duty (variable speed) gearmotors feature either 230 VAC or 230/460 VAC AC 3-phase windings, specifically designed with inverter rated insulation. The special insulation system provides extra protection against high-voltage transients that PWM inverter drives can generate.

By converting the incoming 60 Hz AC power to a DC voltage, inverter drives (also called variable frequency drives) allow AC motors to run at variable speeds, and reduce the inrush of current when the motor starts to rotate. The DC voltage is “chopped” by power transistors (IGBTs) at high frequencies to simulate a sine wave that is then sent to the motor. Varying the output voltage and frequency of the control changes the speed of the motor.

AC Speed Control (VFD) Options

We offer three enclosure types with our AC speed controls. The AC stock controls require minimal set-up and no programming. Most Bodine inverter-duty gearmotor customers use our gearmotors in open-loop velocity control applications, like conveyors, feeders, or metering pumps. We also offer custom OEM solutions where we install encoders and other feedback devices to our inverter duty gearmotors and motors.

V/Hz inverters (basic)

This is the most basic type of drive. V/Hz drives use a pulse-width-modulation scheme to create an output roughly approximating a sine wave of variable frequency, with its amplitude, or voltage, proportional to set frequency. The speed range on V/Hz drives is limited and torque is not easily controlled.

Flux Vector Drive (open loop)

If more accurate and precise motion control is required, a Flux Vector Drive can be used, the basic set-up of these drives is “open-loop” (without an encoder); benefits are tighter speed control, wider speed range, and typically these digital drives come with advanced features like digital readouts, networking cards, and programming features.

Vector Drive System (closed loop)

The most accurate and servo-like performance is obtained from a closed loop vector drive system where an encoder feeds shaft position and rotation information back to the VFD. These closed-loop vector drive systems are more costly and complex systems to set up.

- Check the Line Frequency (Hz) Setting – We have seen situations where an inverter-duty gearmotor was running hot because the inverter was not set up properly to match the voltage and frequency ratings of the motor. Bodine inverter-duty gearmotors are rated at 230/460 V at 60 Hz. The default rating for most motors made for Europe or Asia is 50 Hz. If the inverter is set (or pre-set by the manufacturer) for a motor that is rated for 50 Hz, it will give the gearmotor too much voltage at each frequency setting and can lead to the gearmotor running hotter.

- Check the Nameplate Specifications – Make sure the input voltage to the inverter drive matches the inverter’s and the gearmotor’s voltage ratings and nameplate specifications. Check the user manual for details.

- Check the Voltage and Wiring Diagram – With dual-voltage rated inverter-duty gearmotors or motors with 8-10 motor leads, make sure to use the motor manufacturer’s wiring diagram to properly wire the gearmotor or motor for either 230VAC or 460VAC. Miss-wiring can lead to poor performance, not starting, or to motor or control damage.

- Check the Control Settings – There are many parameters that can be changed in the AC speed control that also affect motor performance and temperature. One example is the Torque Boost setting. At lower speed/frequency settings an inverter-duty gearmotor may not be able to produce the same torque that it can at a higher speed or frequency. The torque boost setting adjusts the output voltage at lower frequency to help the motor generate more torque at those lower speeds

Check these control settings before making any connections:

- Make sure the HP, voltage, and frequency jumpers match the motor nameplate and power source.

- If you are using a GFCI, select the correct jumper for the switching frequency.

- Select Constant Torque or Variable Torque depending on the application.

- Check the automatic restart setting

- Check the Run/Fault output contact settings and programming

5. Check the Rated Speed – Inverter-duty gearmotors will get hot, especially TEFC motors or gearmotors that operate between 10-90Hz. All our inverter-duty gearmotors are designed for continuous duty operation at their rated speed and frequency range (10-90Hz). Check the Safe Operating Area (SOA) graph for the gearmotor/motor to ensure that the gearmotor operates within its capabilities.

To download this blog article as a PDF, please click here.

Copyright Bodine Electric Company © 05/2020. All rights reserved.

The post AC Inverters (VFDs) for Variable Speed Applications appeared first on Bodine - Gearmotor Blog.

]]>The post New Gearmotor Selection and Application Guide appeared first on Bodine - Gearmotor Blog.

]]>

The goal of this guide is to make sure that your design, your gearmotor selection, and your overall motor application performs to specification, and most importantly, to your and your customers’ expectations. After all, we are here to help you make your products and your business a success!

Some of the topics covered in this new PDF download are:

- Gearmotor Mounting Orientation

- Impact of Lubricant on Gearhead Life

- Duty Cycle Considerations

- Gearhead Efficiency and Noise

- Gearhead Life & Brush Life

- Ambient Temperature

This guide also provides a brief overview of the features and benefits of our over 1,300 standard/stock Fractional HP gearmotor catalog options:

We are concluding our Gearmotor Selection Guide with a few real-life application examples, and how we helped our customers to solve various design challenges:

- Automated Bag Sealer Equipment

- Medical Equipment Manufacturing

- AGV (Automated Guided Vehicles / Warehouse Automation)

- Conveyor Equipment

If your application requires a custom design solution, we have experienced application and design engineers ready to assist you with your design and application questions. Call us today, or drop us a line. We would love to hear from you.

Click on this link to download our new gearmotor guide and share the knowledge! Thank you!

Copyright Bodine Electric Company © 05/2020. All rights reserved.

The post New Gearmotor Selection and Application Guide appeared first on Bodine - Gearmotor Blog.

]]>The post Gearmotor Winding Options – AC, PMDC, and BLDC (EC) appeared first on Bodine - Gearmotor Blog.

]]>

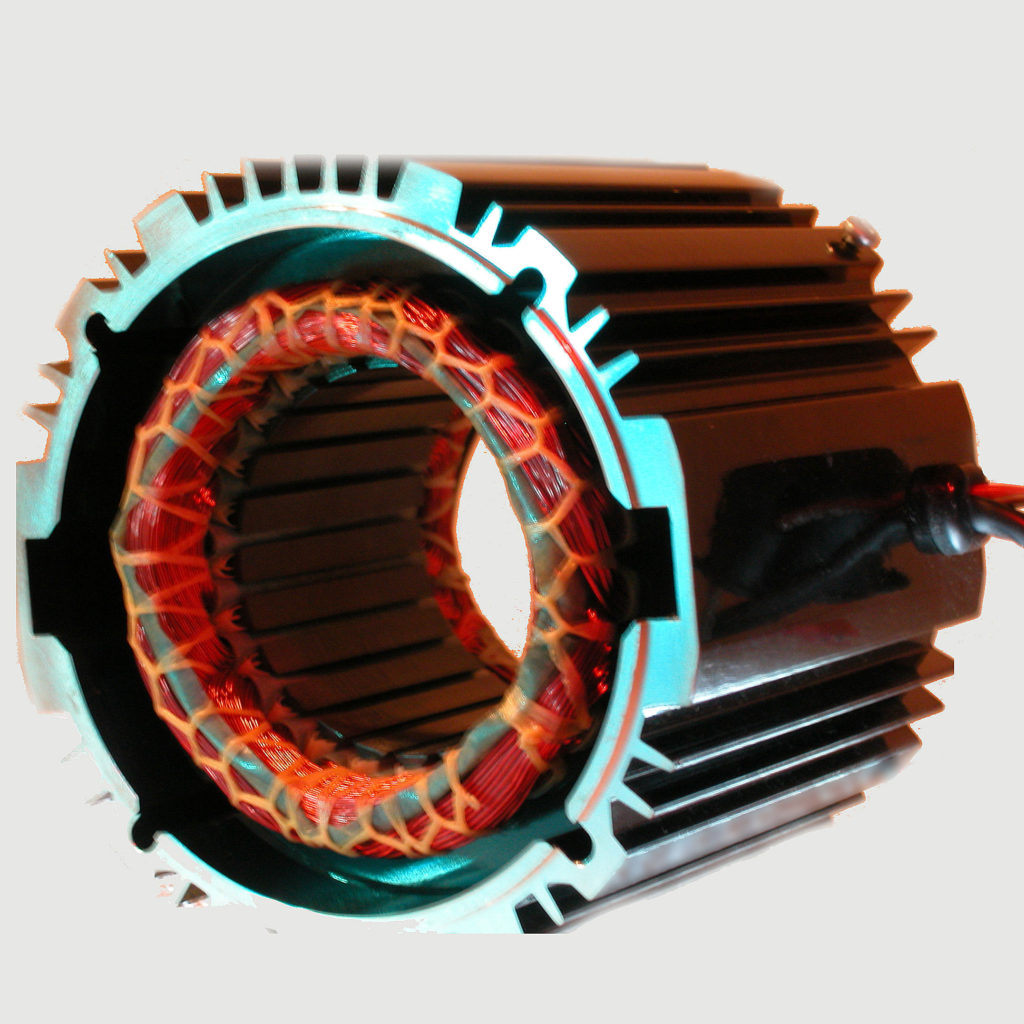

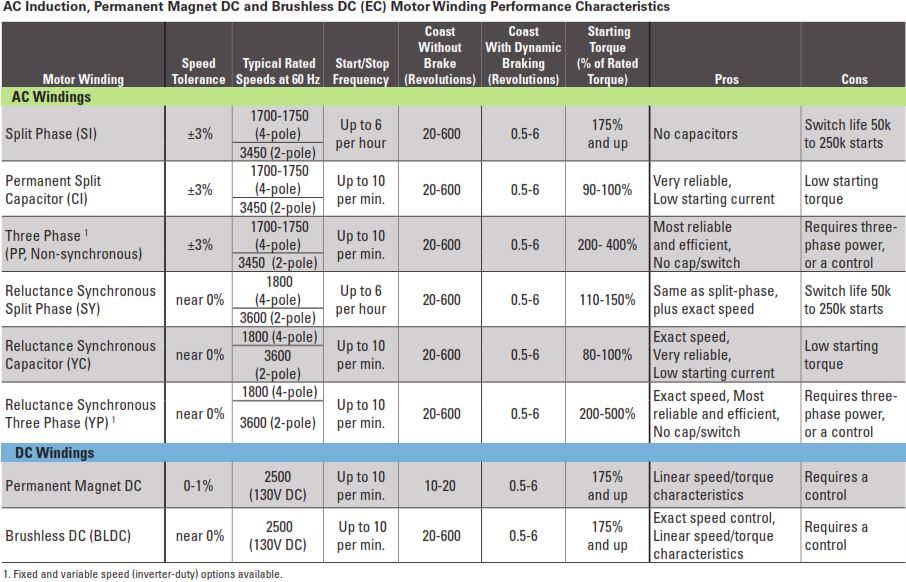

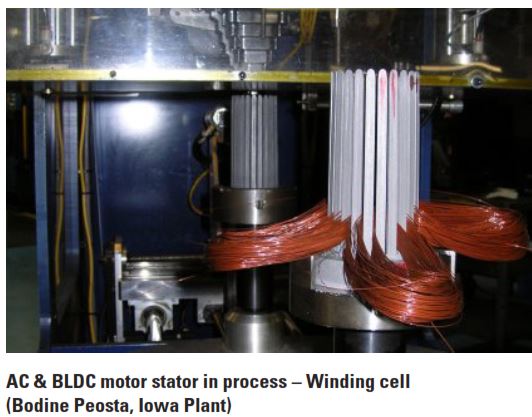

Winding design is one of the major factors that determines gearmotor performance. For example, the windings may be driven by AC or DC current. They may require a capacitor, or a control to run, and may be configured as single, split- or three-phase systems. Some motor types provide precise speed and position control, while others are less accurate. They may be built to run at either a constant or variable speed. Understanding these differences is critical to selecting the right gearmotor for your application.

As a manufacturer that exclusively focuses on fractional horsepower (less than 1 HP/746 Watts) products, Bodine Electric Company offers a range of standard gearmotors and motors with the most common voltage and frequency ratings for both the North American and International markets. Bodine Electric also has the engineering expertise to design and manufacture a great variety of custom winding types and ratings.

AC Induction

AC windings are available in single-phase, two-phase, and poly-phase (three-phase) designs including the following types; split-phase (with centrifugal start switch), capacitor start, permanent split capacitor, 2 capacitor start, 2 capacitor start / one capacitor run, and reluctance synchronous.

These windings can be produced in 2-, 4-, 6- & 8-pole configurations and can be rated as continuous duty, intermittent duty, inverter-duty, dual voltage, dual frequency and fixed or variable speed. Our AC windings are available in voltages ranging from 12 to 575 VAC. Bodine Electric Company also provides solutions for OEM applications that require thermal overload protectors with manual or automatic resets, or simple temperature limiting switches.

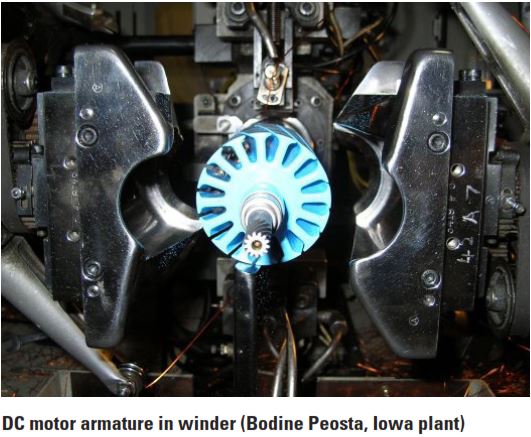

Permanent Magnet DC

PMDC motors are available with rated voltages from 12 to 240 VDC. They can be designed in 2 & 4 pole versions and in lap or wave (4 brush vs. 2 brush) configurations. Multiple magnet grades are available for enhanced performance or added demagnetization protection. End-of-life signaling brushes, and a new proprietary brush wear sensor system are also available from Bodine Electric Company.

Brushless DC (EC)

Our standard brushless DC windings are 3-phase, 4-pole designs (standard voltages are 24 VDC and 130 VDC). Custom designs with voltages ranging from 12 VDC to 260 VDC, and horsepower ratings up to 1 HP/746 Watts, and 8-pole designs are also available. Commutation angle is 60 degrees (standard), and 120 degrees optional (standard on our stock 22B-60P planetary geared motors).

In addition, we also offer our unique 24 VDC INTEGRAmotor product line of brushless DC motors with built-in motor speed control and motor feedback device. Our type 22B/FV and 34B/FV INTEGRAmotors combine a 24VDC brushless DC motor, a built-in, open loop, voltage mode PWM controller and a 1024 PPR, two channel quadrature optical encoder. They accept PWM input from an external motion or speed controller, and feature amplifier enable, direction and dynamic braking inputs, as well as fault signal outputs. The Bodine type 22B/SR and 34B/SR motors and geared motors combine a 24VDC brushless DC motor with a built-in, 0-5 VDC analog input SR control.

If you would like to download this blog article as a PDF, click here.

Copyright Bodine Electric Company © 04/2020. All rights reserved.

The post Gearmotor Winding Options – AC, PMDC, and BLDC (EC) appeared first on Bodine - Gearmotor Blog.

]]>