Planetary Gearmotors Deliver Precise Motion

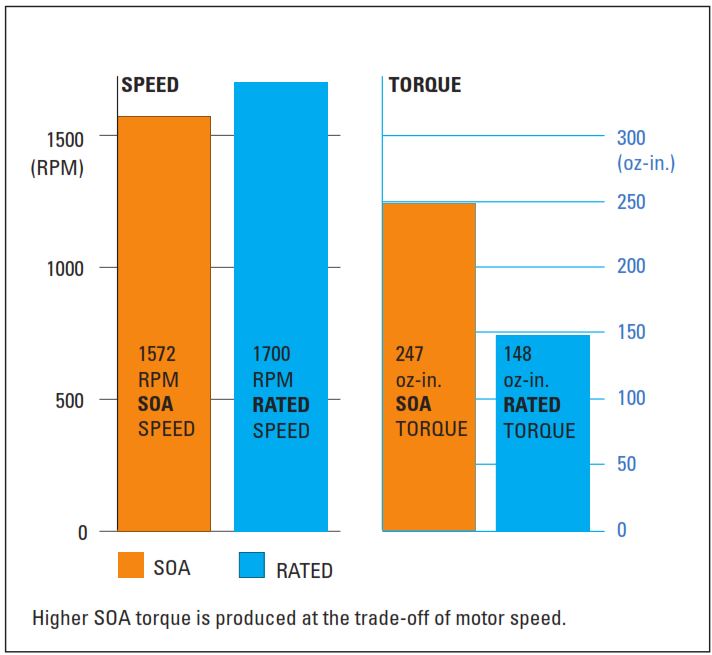

24 VDC gearmotors provide precise positioning for mobile motion control application: A manufacturer of mobile antenna systems required two gearmotors to position the antenna to connect to orbiting telecommunications satellites. The gearmotors deliver precise motion during the initial calibration with the satellite, and then remain idle until the antenna is moved to a new location.VIEW